-

Dimensions (incl. mounted control cabinet):

Approx. 1200 x 1200 x 2200 mm (LWH) -

Weight:

Approx. 600 kg -

Components:

- LPS TT - Steam Turbine

- CW-pump

- Vacuum pump

- Plate cooler

- Condensate tanks

- Control cabinet including inverter

-

External (not included in above):

- Feed water tank (about 200 L)

- WHR steam boiler (plus control instruments)

- Cooling water supply, depending on application

Generating electric power from exhaust waste heat

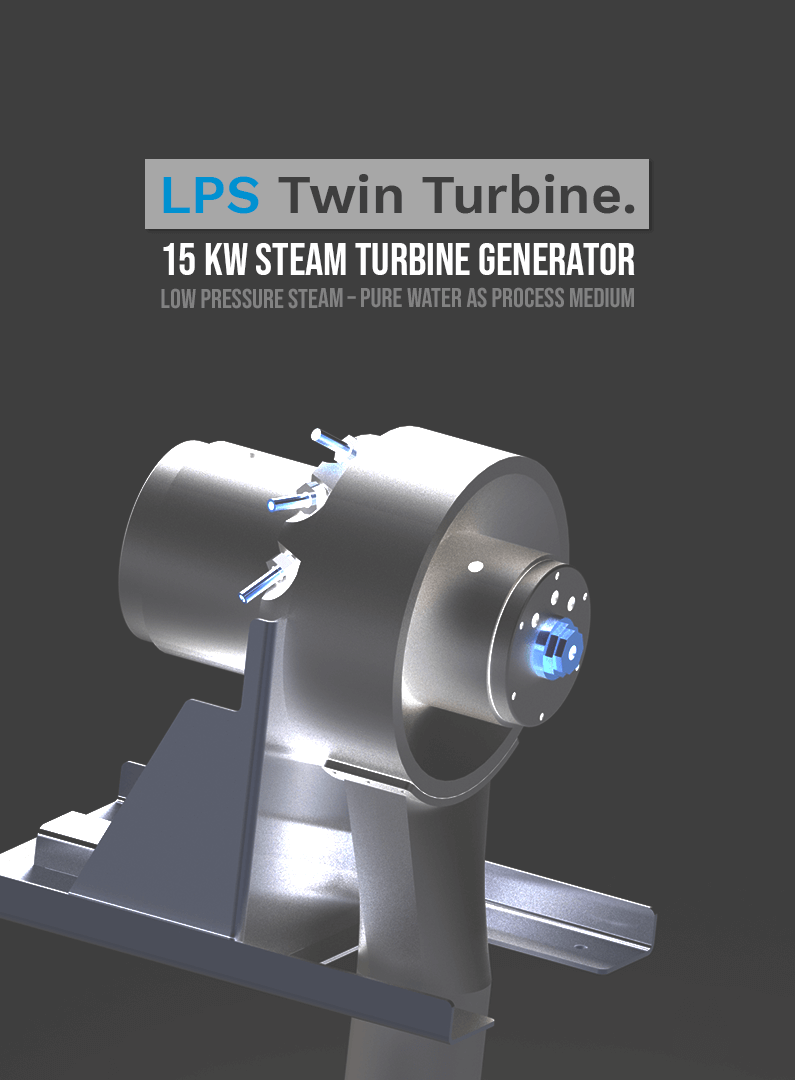

The LPS Twin Turbine uses Low Pressure Steam to increase efficiency of Internal Combustion Engines.

The most modern Internal Combustion Engines have an efficiency of almost 50% and for the older engine designs this is around 40% or even 30%. With the remaining energy being lost to cooling water and exhaust gas.

The LPS Twin Turbine (previously Green Turbine) reduces losses and emissions to air, thereby increasing efficiency with 6-9% of installed engine power depending on engine design, exhaust gas temperature and engine load.

Today, the return on investment for a LPS Twin Turbine system is between 2 and 4 years. It is depending on the cost of fuel, operational profile and engine data. Please contact us for a custom evaluation.

Looking ahead, the return on investment will reduce quickly, as both future fuel cost and Emission Trading Schedules are currently on the rise.

Planning to install scrubbers in your smoke stack? We have smart scrubber solutions available and our steam based system delivers an excellent opportunity to earn back the bills of your scrubber investment.

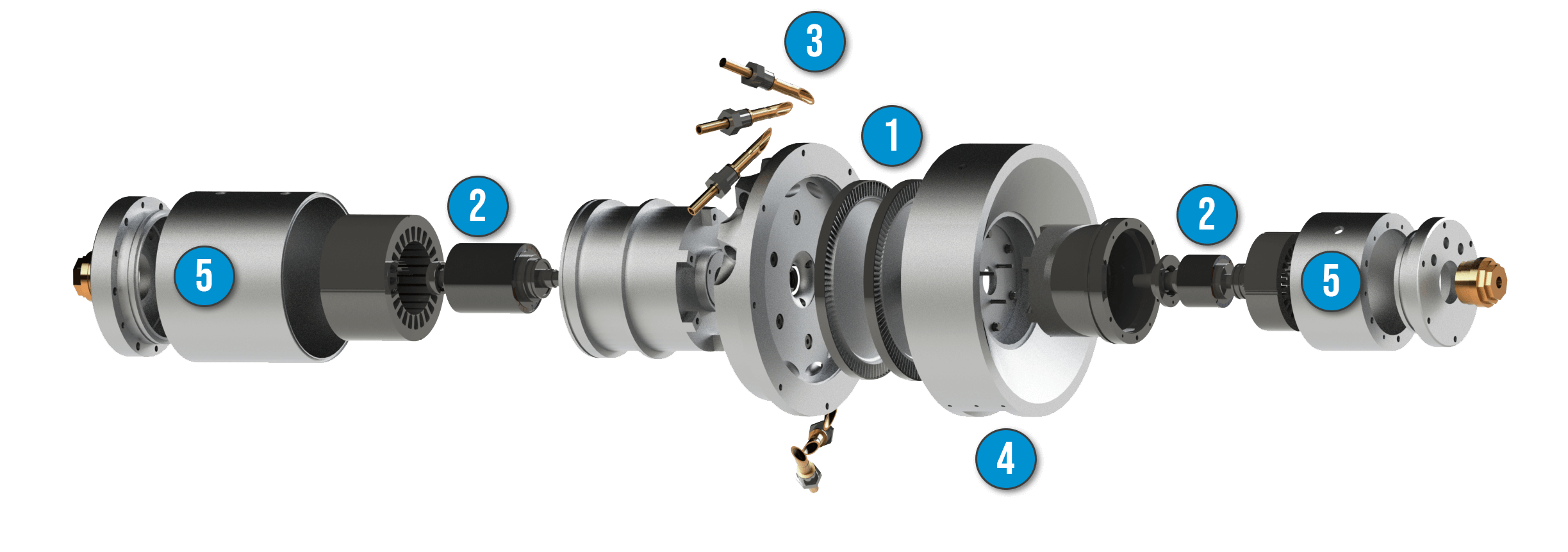

Components

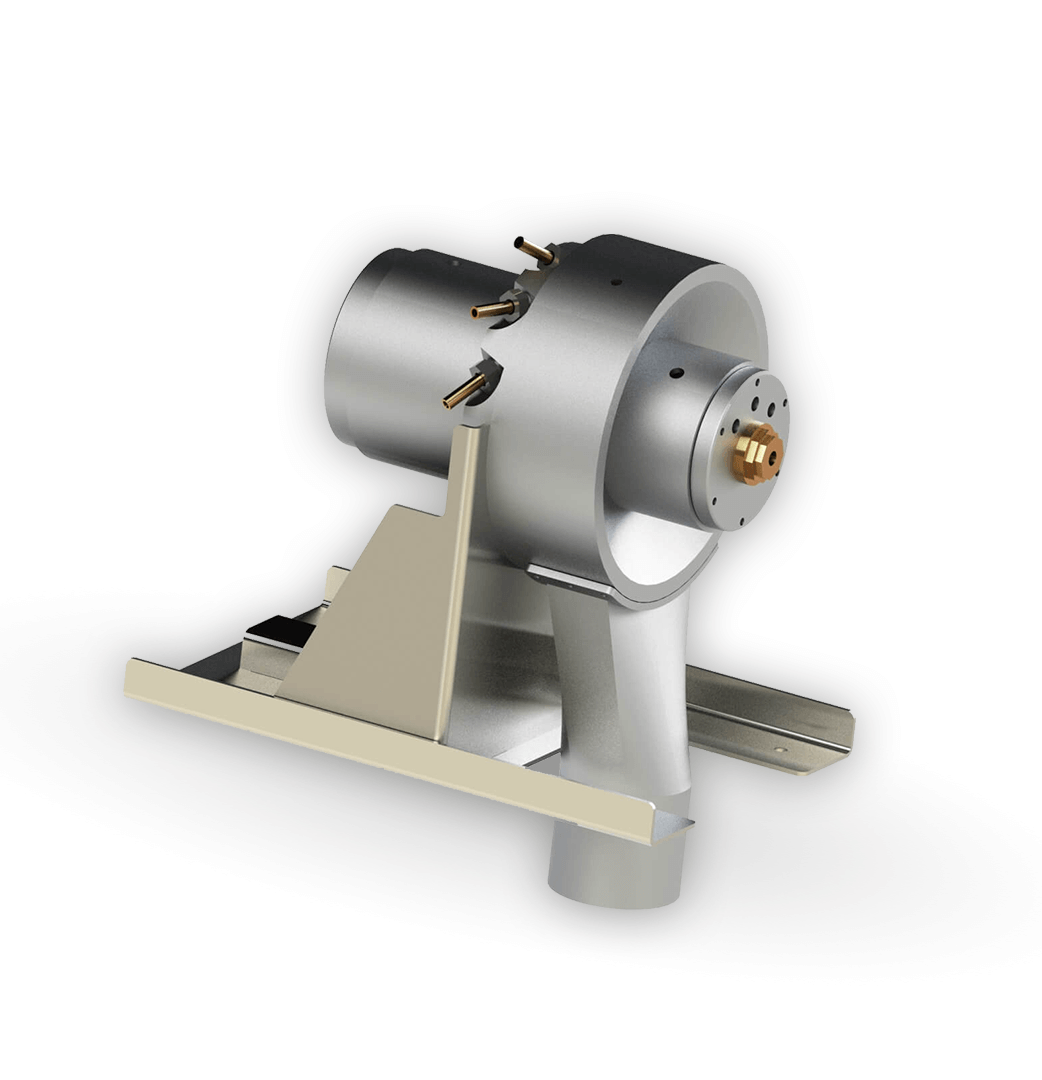

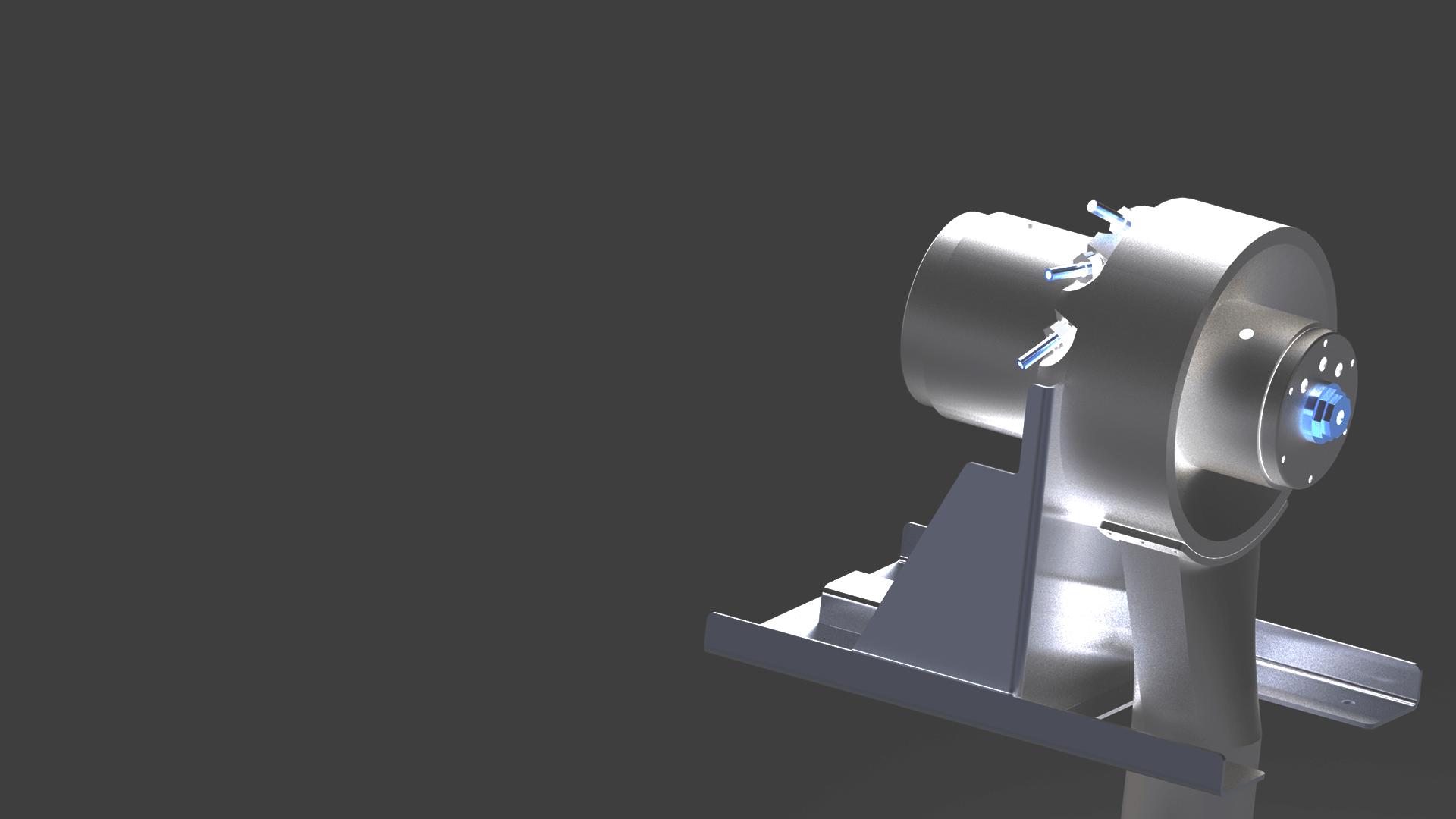

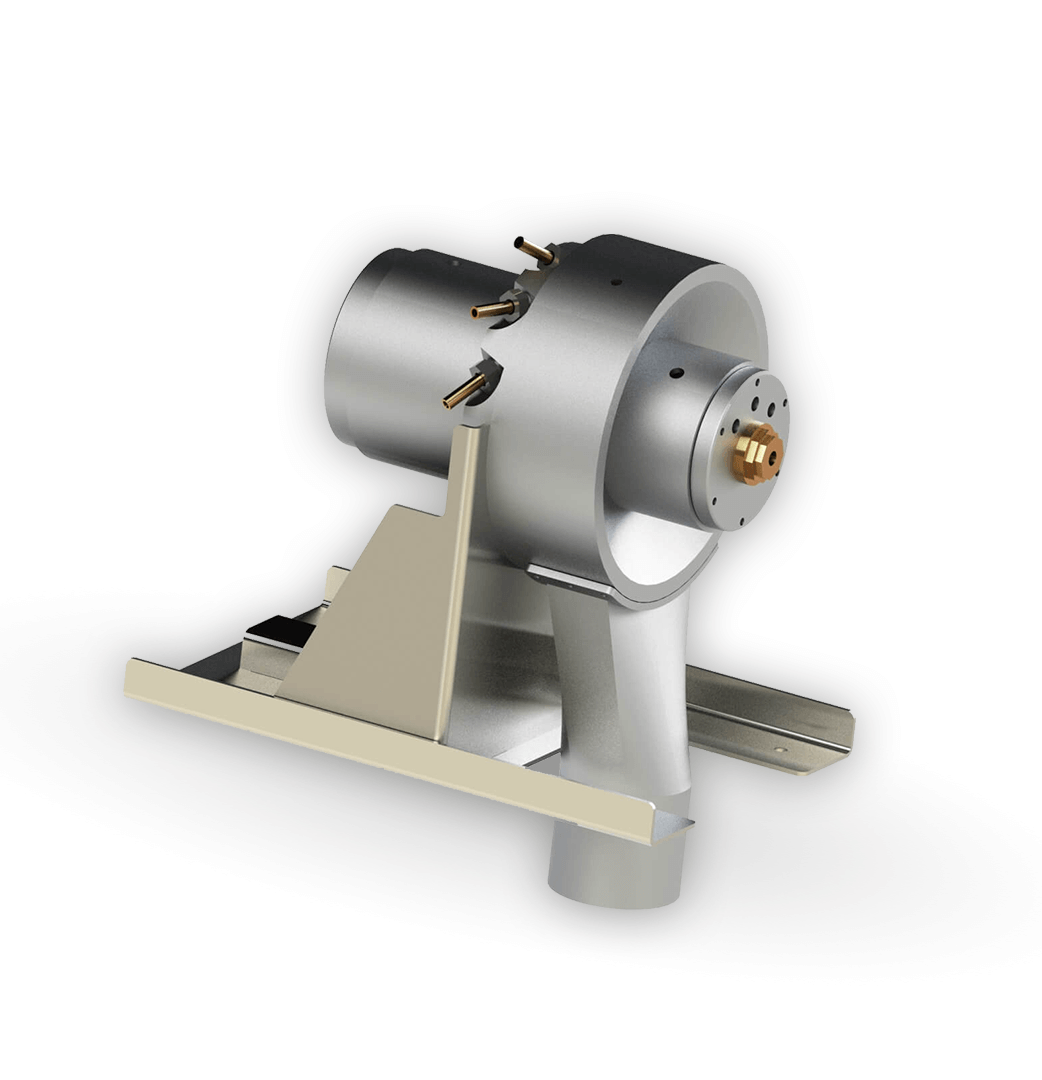

The heart of the Twin Turbine are the counter rotating turbine wheels (1). Each turbine wheel direct drives its own generator and there are no gear wheels or any other complexities in the design, ensuring ease of maintenance and reliability. The weight of the turbine generator is only 25 kg / 55 lbs making it easy to handle. The "twins" of the Twin Turbine can be separated by taking out eight bolts.

The process medium of the turbine is demineralised water without any additives. There are thus no hazardous substances released during maintenance or operation. The system is a closed loop system and suppletion is limited to the low system losses. If it is required to top-up the system then the cost of demineralised water is the lowest of any process medium used in the waste heat recovery industry.

- Twin turbine wheels

- Twin generators

- Steam inlet jets

- Exhaust

- Water cooling

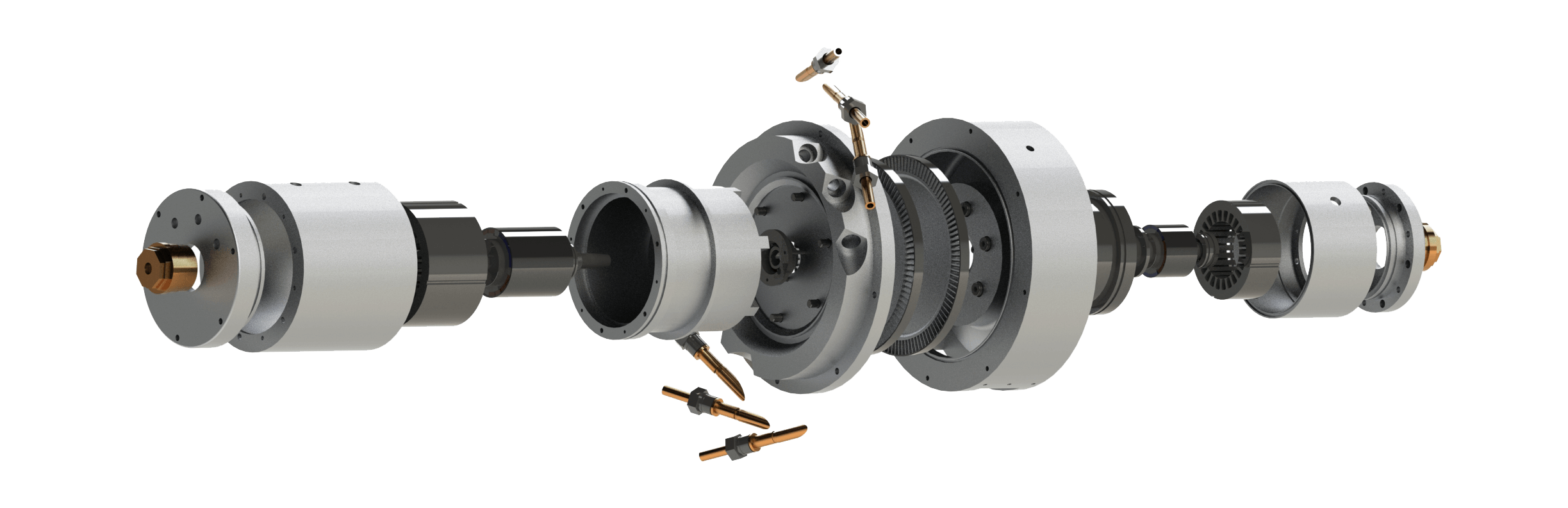

The counter-rotating twin turbine wheels are seen in the center, with the twin generators, in black, at the far left and the far right. The turbine wheels are not connected and there is no stator in between the wheels. Each wheel is fitted on its own generator shaft. This makes maintenance extremely easy: after taking out the 8 bolts that tie the housing together, the turbine can be split in the twin turbine generator sections.

Specifications

Specifications of the 15 kWe unit:

| Metric | Imperial | |

|---|---|---|

| Design turbine speed | 26.000 rpm | 26.000 rpm |

| Dimensions turbine | 370 x 260 x 260 mm (LWH) | 14,6" x 10,2" x 10,2" |

| Weight turbine | 25 kg | 55 lbs |

| Inlet steam pressure / temperature | 10,5 bar (a) / 227 °C | 140 psi (a) / 440 °F |

| Outlet steam pressure / temperature | 0.05 bar (a) / 45 °C | 0.7 psi (a) / 113 °F |

Skid

The LPS Twin Turbine is delivered in an autonomous system layout that provides electric power to the (local) grid and automatically follows the load changes of the main combustion process. Remote monitoring and start/stop is available through an LAN-internet connection. The standard skid dimensions are given below. Custom dimensions are available on request.

Current development status

- The 15 kWe system is tested in laboratorium conditions and in the field. It is currently available for purchase.

- The 30 kWe and 100 kWe versions are now in development.

- The 100 kWe development is part of a consortium effort brought together by a blue chip company working with agricultural off-grid locations in the developing world.

- One of the reasons why this consortium selected the LPS Twin Turbine is the simplicity of the design which allows for user maintenance.

- The reliability of turbines in general and the clean and widely available process medium are the additional benefits for this use case.

- The 30 kWe version will be available end 2023, not much bigger than the 15 kWe unit.